Learn the top 3 advantages of 3/8 engineered hardwood that make it a popular flooring option.

Choosing the right flooring can change how your home looks and feels. The 3/8 inch hardwood is popular because it’s affordable yet beautiful. It’s a middle ground between cheaper options and more expensive thick planks.

3 8 engineered hardwood is not just about looks. It combines the warmth of real wood with modern engineering for extra strength. The 3/8 inch thickness is durable but easy to install.

Whether you’re renovating or building a new home, 3/8 inch hardwood is versatile. The engineered wood flooring market is growing. More people are seeing its benefits for busy homes and changing seasons.

Key Takeaways

- 3 8 engineered hardwood offers the perfect balance between quality and value

- This thickness works well in most residential applications

- Engineered wood flooring provides greater stability than solid hardwood

- The 3/8 inch option is compatible with various installation methods

- It uses less wood than solid options, making it more eco-friendly

- This flooring type performs well in areas with humidity changes

Understanding What 3 8 Engineered Hardwood Is and How It’s Made

Engineered hardwood is a modern twist on traditional wood floors. It’s made of layers, not just one solid piece. This design makes it more stable and keeps the wood’s natural beauty.

The Structure and Composition of Engineered Hardwood

Engineered flooring has a special layered design. The top layer is real hardwood, showing off the wood’s grain and character. Below, plywood layers add stability.

What Makes 3/8 Inch Thickness Special

The 3/8 inch thickness is just right. It’s thick enough for sanding but thin for easy installation. This makes it great for renovations where floor height is important.

Manufacturing Process and Quality Standards

It starts with top-quality wood for the veneer and plywood core. These are bonded together using heat and pressure. Quality engineered hardwood is tested for stability and finish durability.

Look for products certified by the National Wood Flooring Association. This ensures they meet high standards for quality and the environment.

Reason One: Superior Stability in Various Environmental Conditions

The 3/8 engineered hardwood flooring is incredibly stable. It’s much better than solid wood in many ways. This is because of its special cross-directional plywood core. Each layer is set up to balance out the others, making it hard for the floor to move.

How 3/8 Engineered Hardwood Resists Warping and Expansion

Unlike solid hardwood, engineered wood doesn’t expand and contract as much. This is because of its layered design. The 3/8-inch thickness is just right – thick enough to stay stable, but thin enough to barely change with humidity.

The core layers push against each other when it gets wet. This stops the wood from swelling. This means the floor won’t cup, crown, or gap like solid wood floors often do.

Video source from Youtube

Performance in Humid Environments

Places like basements, kitchens, and bathrooms used to be off-limits for hardwood. But 3/8 engineered flooring changes that. It can handle up to 75% relative humidity without losing its shape.

Coastal homes and places with big humidity swings also benefit. The floor stays looking good and strong, even when the weather changes a lot.

Compatibility with Radiant Heating Systems

One big plus of 3/8 engineered hardwood is how well it works with radiant heat flooring. Its thin profile lets heat spread easily, but it’s made to avoid the cracks and splits solid wood gets from heat changes.

The 3/8-inch thickness is perfect. It’s thick enough to feel like real wood, but thin enough to let heat through. This makes it great for radiant heating systems, keeping your floors warm and looking good.

Reason Two: The Perfect Balance Between Durability and Installation Flexibility

The 3/8 inch engineered hardwood is both durable and easy to install. Its wear layer is thick enough for many refinishing cycles. This makes the floor last longer than thinner options.

This thickness also gives a solid feel underfoot. Yet, it’s not as hard to install as thicker products.

When it comes to installing engineered flooring, 3/8 inch is a top choice. It works well with different installation methods. This makes it perfect for DIY projects.

For a more permanent fix, you can glue the floor down. This method is great for concrete subfloors. Nail-down installation is also an option for wood subfloors.

Professionals like this option because it’s versatile. It works well with various subfloor conditions in one project. The thickness adds stability without losing flexibility.

| Installation Method | Best Subfloor Type | Key Advantage |

|---|---|---|

| Floating | Most existing floors | Quick installation, no adhesives |

| Glue-down | Concrete | Superior stability |

| Nail-down hardwood | Wood subfloor | Traditional security |

The 3/8 inch flooring also absorbs sound well. It’s thin enough for easy transitions to other floors. This means you won’t have to adjust doors during installation.

This balance makes 3/8 inch engineered hardwood great for renovations. It’s durable and easy to install. This offers long-term value without the hassle of complex installations.

Reason Three: Eco-Friendly and Sustainable Flooring Option

Many people choose 3/8 engineered hardwood for its eco-friendly benefits. It uses less wood than solid hardwood but still looks beautiful. This makes it a great choice for those who care about the environment.

Reduced Wood Usage Compared to Solid Hardwood

3/8 engineered hardwood is made in a way that uses more of the tree. One log can make up to five times more sustainable hardwood flooring than solid planks. This means fewer trees are cut down for the same amount of flooring.

Responsible Forestry Practices in Production

Quality makers use FSC certified hardwood in their products. This ensures the wood comes from forests that are managed well. These forests are good for the environment, people, and the economy.

When you’re looking for eco-friendly wood floors, check for these certifications:

- Forest Stewardship Council (FSC)

- Programme for the Endorsement of Forest Certification (PEFC)

- Sustainable Forestry Initiative (SFI)

Indoor Air Quality Benefits

Many 3/8 engineered hardwoods are VOC-free flooring options. They have cores that don’t release harmful gases. This makes the air inside your home cleaner.

These floors also have finishes that are safe for your health and the planet. Plus, they last longer than other options. This means you don’t have to replace them as often.

| Environmental Aspect | 3/8 Engineered Hardwood | Solid Hardwood |

|---|---|---|

| Wood Usage | Efficient (3-5x more flooring per log) | Higher consumption |

| Certifications | FSC, PEFC available | Available but less common |

| VOC Emissions | Low to zero options | Varies by finish |

| Replacement Frequency | Lower (15-25 years) | Higher in moisture-prone areas |

Installation Methods for 3 8 Engineered Hardwood

3/8 engineered hardwood is versatile in its installation options. It fits well in different home settings. Homeowners can pick from several methods based on their subfloor and personal taste.

- The floating floor system doesn’t need to be stuck to the subfloor. Instead, planks connect to each other. This allows for natural movement and is good over concrete, existing floors, or wood subfloors.

- Glue-down hardwood installation makes planks stick to the subfloor with special glue. It creates a solid, quiet floor perfect for busy areas.

- Nail-down installation secures planks to wood subfloors with cleats or staples. It offers traditional strength and durability.

For DIY wood floor installation, the floating method is easy for beginners. With simple tools and careful prep, homeowners can get good results. The click-lock systems make the process cleaner and easier.

Professional hardwood installation is the best choice for perfect results. Experts use special tools, prepare subfloors well, and handle details like transitions and trim. While it costs more upfront, the long-term benefits of better durability and look are worth it.

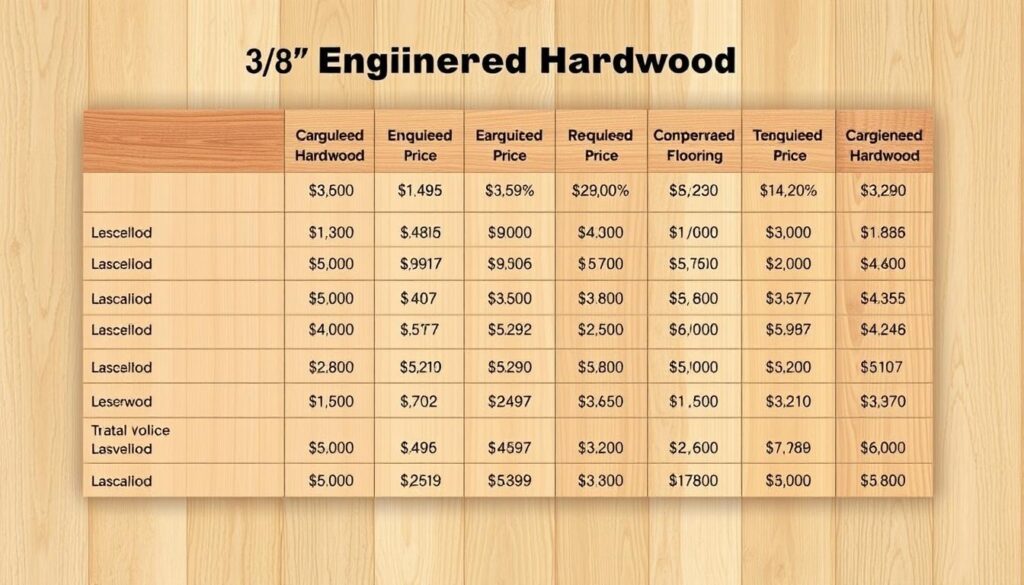

Cost Analysis: What to Expect When Buying 3 8 Engineered Hardwood

Understanding the cost of 3/8 engineered hardwood is key to a smart home choice. The cost includes the initial purchase, installation, and long-term value. These factors impact the overall value of your flooring.

Initial Purchase Price Range

Engineered hardwood prices vary from $3 to $14 per square foot. This depends on the wood type, finish, and brand. Premium woods like maple or walnut cost more, while oak is mid-range. Budget-friendly options start at $3-$5 per square foot, making it more affordable than thicker options.

Installation Costs Breakdown

Installation costs range from $3-$8 per square foot with professional help. Prices change based on:

- Subfloor preparation needs

- Room layout complexity

- Regional labor rates

- Extra materials needed (underlayment, trim, adhesives)

DIY installation can save money but requires the right tools and skills. Click-lock systems in 3/8 engineered products are easier and cheaper than nail-down methods for thicker floors.

Long-term Value and Return on Investment

Engineered hardwood is a wise investment. It returns 70-80% of its cost at resale, boosting your home’s value. The 3/8 thickness offers a good balance of cost and durability, lasting 20-30 years with care. This makes it a cost-effective choice over shorter-lived options like carpet or vinyl.

Maintenance and Care Tips to Extend the Life of Your Flooring

Proper care turns your 3/8 engineered flooring into a lasting investment. Daily, sweep with a soft-bristle broom or vacuum with a floor attachment. This prevents grit from scratching the surface.

When cleaning, use products made for wood surfaces. Avoid too much moisture, steam cleaners, or vinegar. A slightly damp microfiber mop with a cleaner approved by the manufacturer is best for daily cleaning.

Wood floor protection starts with simple steps:

- Place felt pads under furniture legs

- Use area rugs in high-traffic zones

- Remove shoes, especially high heels

- Maintain indoor humidity between 35-55%

- Clean spills immediately

The 3/8 thickness affects refinishing options. Most 3/8 products can handle 1-2 light sandings. Look for dullness, deep scratches, or consistent wear to know when to refinish.

Seasonal changes are important too. Use humidifiers in winter to prevent wood shrinkage. Use dehumidifiers in summer to prevent expansion. This care ensures your floors stay beautiful for decades, making your investment worthwhile.

Comparing 3 8 Engineered Hardwood with Other Flooring Alternatives

When looking at flooring options, it’s key to see how 3/8 engineered hardwood stacks up. It beats solid hardwood in stability and cost for installation, but can’t be refinished as many times. Compared to laminate and luxury vinyl, it looks more like real wood, resists water better, and boosts your home’s value. But, it might cost more upfront.

Engineered vs. Solid Hardwood: Pros and Cons

Solid hardwood is loved for its classic look and ability to be refinished many times. But, 3/8 engineered hardwood is more stable because of its multi-ply design. This design also makes it easier to install, saving on labor costs compared to solid hardwood.

Engineered Hardwood vs. Laminate and Luxury Vinyl

Laminate and luxury vinyl are affordable and water-resistant. But, 3/8 engineered hardwood looks more like real wood and feels better underfoot. It also adds more value to your home than these synthetic options.

Comparing Engineered Hardwood Thicknesses

The 3/8-inch thickness of engineered hardwood is a good mix of stability, durability, and affordability. Thinner options might not be as strong, while thicker ones are pricier and harder to install. The 3/8-inch is a great choice, offering solid performance without breaking the bank.

FAQ

What is the difference between 3/8 inch engineered hardwood and other engineered hardwood thicknesses?

The 3/8 inch thickness of engineered hardwood strikes a perfect balance. It’s stable, durable, and easy to install. Compared to thinner options, it’s stronger and better at sound absorption. It’s also easier to install than thicker options, making it great for different rooms.

How does 3/8 engineered hardwood perform in different environmental conditions?

3/8 engineered hardwood resists warping and expansion well. Its plywood core keeps it stable, even in changing humidity and temperature. This makes it a top choice for areas with moisture issues or radiant heating.

What installation methods are compatible with 3/8 engineered hardwood?

You can install 3/8 engineered hardwood in several ways. It works with floating, glue-down, and nail-down methods. This makes it perfect for both DIY and professional jobs, fitting many subfloor types.

How does the cost of 3/8 engineered hardwood compare to other flooring options?

3/8 engineered hardwood is priced well, offering quality at a good price. It’s more affordable than some luxury options but still offers great value. Its durability and ability to be refinished make it a smart long-term choice.

What are the environmental benefits of choosing 3/8 engineered hardwood?

Choosing 3/8 engineered hardwood is eco-friendly. It uses less wood than solid hardwood but still looks authentic. Many makers use sustainable forestry and low-VOC finishes, improving air quality indoors.

Read also : 3 8 Hardwood Flooring: The Ideal Choice for Your Home